It is practically super cool to bend titanium tubes. With it you can bend long, thin titanium tubes into any shape or angle. Using titanium tube bending makes a lot of sense for a long list of reasons, as this material is exceptional when you consider just how many good things it offers to airplane parts and medical devices all the way down too robots and car parts. This method gets amazing results, if you follow the right expert tip!

Titanium is one of the more popular metals for airplane designers. Why? They are light and strong! Weight, as you know especially on airplanes is everything. Construction of Titanium Tubing Bends Offer an Ideal Solution to Airframe Parts The tubing can be bent in smooth curves, so fewer joints (or connections) are needed to assemble the parts Fewer joints is a big deal because every fastener adds weight to an airplane. The lighter the parts, the faster and farther a plane can fly. Above all, titanium is unique for two reasons: it does not corrode and has very high heat resistance. This makes it rugged and ideal for use in airplanes where durability is key.

It requires both a good deal of work and an abundance of skill to properly bend tubes made from titanium. Those who specialize in this know that the pipe has to be perfectly straight and smooth prior to its being bent. First you want to make sure your tube is clean, it helps with making a good bend and the less chance of the tube cracking or breaking. Proper tools are also required for achieving the best results. Specialists ought to have the option to tell you precisely what points and lengths they need in your unique development project. They also need to know what titanium does, which is very strong and stiff. This is how, they are able to produce tubing that has exact bends!

Those who design and manufacture medical devices need to take care of everything in a clean room. And this is where titanium tube bending comes in, its very helpful for it. Creating a bend radius and other measurements are key to making medical devices that work exactly as they should. The reason titanium is used for these products it due to the fact that this metal has bio-compatibility, which does not irritate human tissue. That is why titanium is great for items like implants and other types of medical instruments that will come in contact with the human body. The methods for bending titanium tubing are unique and special to guarantee that such critical medical tools have been built on the top quality standards.

As you would expect, the robots used in factories and manufacturing facilities are industrial robots. However, they need to move quickly and safely across these environments by using materials that are lightweight yet strong. This criteria of balance matches the properties that titanium exhibits, abilities to be light and super strong. Also, titanium does not corrode easily so it is the best material for complex conditions where machines will deal with various situations. Creating the necessary shapes and angles for robotic parts often requires titanium tube bending. The specific results of titanium tubing bending allow industrial robots to work more effectively and safely- This is very important in factory surroundings.

Although many tune car parts, a great deal of skill and understanding is needed when it comes to customising them. There are a few inherent benefits and reasons why titanium tube bending can work well according to this process: In addition to its strength, titanium is lightweight making it a perfect metal for car parts. To get the optimal results, bend radius and other measurements also have to be controlled. What this means is that professionals experts need to have a vast amount of experience and knowledge just so they get everything right. When finishing up a bent tube, it is absolutely crucial that the clean and finished in high quality. What makes Michelson even more appealing is the fact that it lasts for so long and continues to be strong.

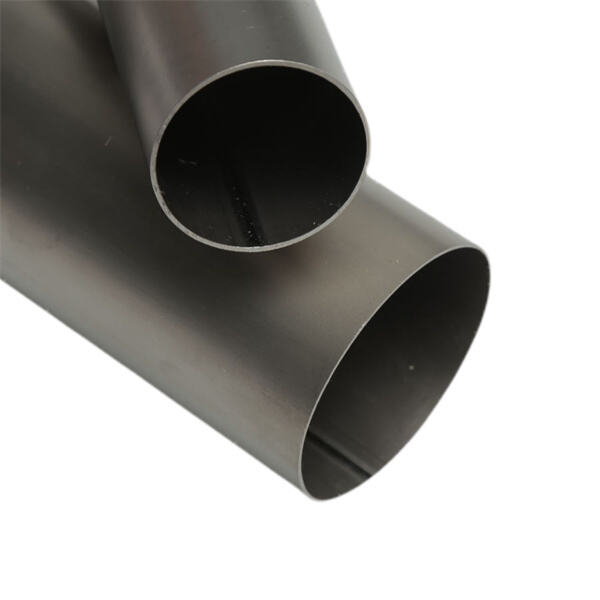

Standard size, custom design tubes are all accepted. We have been in this industry for more than titanium tube bending. We've been a gold dealer on Alibaba for the past 16 years, and we receive high scores of products made of metal. Our products are already exported to over 40 countries, including America, Canada, Germany, U K, France, Portugal, Chile, Japan, Malaysia, and Korea... We provide top quality products at a affordable prices, excellent service, timely delivery and we have earned a good reputation from our customers all over the world.

Our company is pleased to have a team of extraordinary talent that is creative and diligence. Based on a unique management concept and a concept of perspective development we are able to provide titanium tube bending services with high quality and a good reputation. With our constant innovation, we have obtained customers' total praise. All employees in our business will be determined to work for advancement in technology, and contribute to the society, fill the excitement of community. All friends are welcome to come and talk business with us. We would like to welcome you to Channel Industries!

our comprehensive after-sales assistance assures customers of prompt assistance and support throughout the usage of the product our technical support team is ready to help with any technical problems or problems with use we also offer titanium tube bending training and technical support for customers to better understand and use our products if you select with us you'll get not only high-quality products as well as comprehensive after-sales services and technical assistance ensuring that you feel our professionalism and devotion with every usage

ZhangjiagangChannel Int'l Co., Ltd. A seasoned metal tube producer is principally involved in metal and nonferrous metal products. Channel Industries can supply whole assortment of metal products. These including titanium tube bending titanium tube, aluminum tube, copper tube, nickel alloy strip/coil sheet and bars. The "Key-Project" technology, production equipment line and the above products. We are able to meet the requirements of ASTM, DIN, EN, JIS standard.