Custom Tube Manufacturing: Making Metal Tubes in Unique Shapes and Sizes There is much that can be done with them, be it construction, automotive, or even fashionable jewelry. This text goes over how to create custom metal tubing from a company known for being a great tubing company, referred to as Channel.

What You Need to Know About Custom Metal Tubing Manufacturing

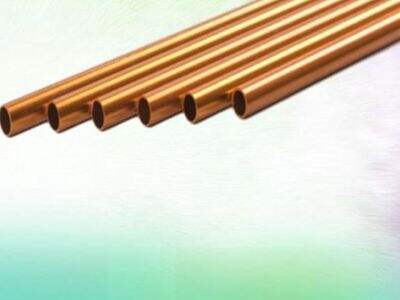

Choosing the right metal type is essential for fabricating custom metal tubing. Metals vary quite a lot in properties, such as tensile and ductility. Needless to say, you should select the metal that best serves your purpose for the use of tubing. For example, channel can be composed of stainless steel, aluminum, copper, and many other available kinds.

Once you have chosen the metal comes the next step in which you need to cut the metal to the right length and shape. This can be performed with tools such as saws or lasers. To ensure precise metal cutting, Channel utilizes the finest equipment.

Custom Metal Tubing Production Process Steps

After being cut, the metal is shaped into a tube through a process known as tube bending. That involves bending the metal around a form to shape the tube you’re after. Channel has several skilled craftsmen who specialize in bending tubes using various methods and at many angles.

The next step is welding. Welding is the process of joining two pieces of metal with heat. This creates a nice fit between the pieces and makes sure the tube will survive for some time. Channel uses advanced welded techniques to create high-quality metal tubing.

Points to Consider When Selecting Metal for Tubing

In viscosity, oval aluminium tube there are some primary factors to consider When making decisions about metal for tubing. One is what the tubing is going to be used for. For instance, if it’s going to be in a damp location, you need to choose a metal that doesn’t rust, such as stainless steel.

The other consideration is how thick the metal is. Different metals are strong to different extents, so you'll need to choose a metal strong enough for whatever you'll use the tubing for. Channel's seasoned professionals are here to help you choose the proper metal to suit your specifications.

Custom Metal Tubing: Techniques for Making Metal Tubing

Custom aluminium tube requires precise work and attention. One method used to conform metal into complex shapes is hydroforming, where high-pressure fluid is used to shape the metal. This design method provides more creative designs and enables tubes with smooth joints.

Another process is drawing, where the metal is pulled through a shape to produce a tube. This technique encourages uniform thickness and precision dimensions for the tubes. They are familiar with hydroforming capabilities, as well as drawing techniques.

Beds: Accurately Manufacturing Custom Metal Tubing

Good materials and advanced methods are necessary to ensure aluminium round tube is accurate and functions well. Channel uses only the finest materials and tools to produce tubing that meets high quality and performance standards.

Custom metal tubings are fabricated through a precise process requiring attention and expertise. Channel, for example, can assist you in producing customized metal tubing that meets your requirements. Channel knows its tubing and how to use it for all your car and building needs and more!